nCa-AI Collaborative Report

1. What Are Polymers in General?

Polymers are macromolecules formed by repeating monomer units linked via covalent bonds. They include natural polymers (e.g., cellulose, proteins) and synthetic ones (e.g., polyethylene, nylon), distinguished by high molecular weight, which confers properties like flexibility, strength, and durability. Synthetic polymers, often derived from petrochemicals, dominate modern applications in plastics, fibers, rubbers, and coatings due to their tunable characteristics.

| Table 1 – Types of Polymers | |||

| Type | Examples | Source | Common Uses |

| Natural | Cellulose, Chitin | Plants, Animals | Paper, Textiles |

| Synthetic | Polyethylene, Nylon | Petrochemicals | Packaging, Clothing |

| Semi-Synthetic | Rayon, Cellulose Acetate | Modified Natural | Fabrics, Films |

Source: Painter, P. C., & Coleman, M. M. (2008). Fundamentals of Polymer Science: An Introductory Text.

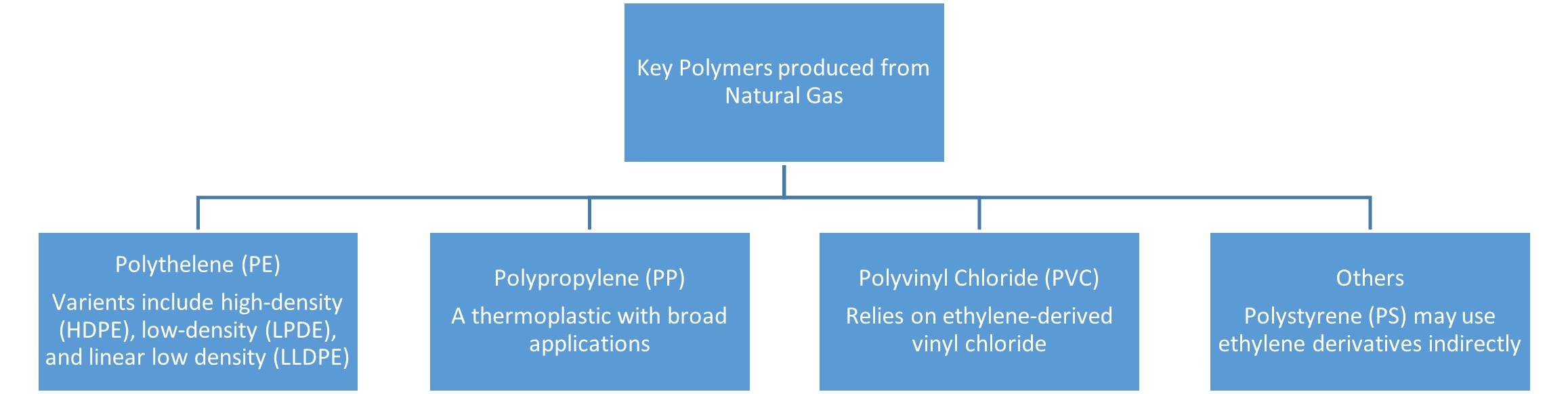

2. Polymers Produced from Natural Gas

Natural gas, primarily methane with natural gas liquids (NGLs) like ethane and propane, is a key feedstock for polymers such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) precursors. Ethane is cracked into ethylene, the building block for PE and PVC intermediates (e.g., vinyl chloride monomer). Propane yields propylene for PP. These polymers account for a significant share of global plastic production.

Source: U.S. Energy Information Administration (EIA). (2024). Natural Gas Liquids Primer.

3. What Is the Process of Their Production?

Producing polymers from natural gas involves multiple stages:

a. Extraction and Processing:

– Natural gas is extracted via drilling and processed to isolate NGLs (ethane, propane).

– Methane is typically used for energy or methanol production.

b. Cracking:

– Ethane/propane undergo steam cracking at 800–900°C to produce ethylene/propylene.

– Reaction: C₂H₆ → C₂H₄ (ethylene) + H₂

c. Polymerization:

– Ethylene is polymerized using catalysts (e.g., Ziegler-Natta) to form PE.

– Propylene is polymerized into PP.

– For PVC, ethylene is converted to vinyl chloride monomer (VCM) via chlorination, then polymerized.

d. Compounding and Fabrication:

– Polymers are mixed with additives (e.g., stabilizers) and shaped into pellets, films, or products.

Chart 1: Simplified Production Process Flow

Source: Perry, R. H., & Green, D. W. (2018). Perry’s Chemical Engineers’ Handbook.

4. What Are the Uses of Polymers Produced from Natural Gas?

Natural gas-derived polymers are critical across industries:

– Polyethylene (PE):

– Packaging (bags, films, bottles)

– Construction (pipes, geomembranes)

– Agriculture (mulch films)

– Polypropylene (PP):

– Automotive (bumpers, interiors)

– Textiles (carpets, nonwovens)

– Packaging (containers)

– Polyvinyl Chloride (PVC):

– Construction (pipes, window frames)

– Medical (tubing, IV bags)

– Electrical (cable insulation)

| Table 2: Polymer Uses by Industry | |||||

| Polymer | Packaging | Construction | Automotive | Medical | Textiles |

| PE | ✓ | ✓ | ✓ | ✓ | X |

| PP | ✓ | ✓ | ✓ | ✓ | ✓ |

| PVC | ✓ | ✓ | X | ✓ | X |

Source: Grand View Research. (2023). Polyethylene Market Size, Share & Growth Report, 2030.

(https://www.grandviewresearch.com/industry-analysis/polyethylene-pe-market)

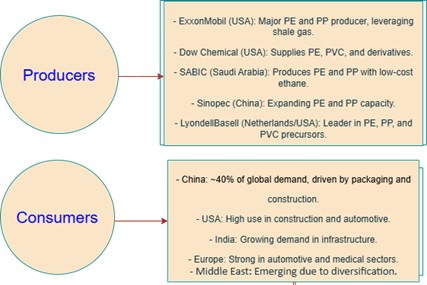

5. Who Are the Major Producers and Consumers?

Source: Chemical Market Analytics. (2023). Plastics and Polymers Global Market Analysis. (https://chemicalmarketanalytics.com/value-chain/plastics-polymers/)

6. How Much Natural Gas Is Required to Produce What Volume of Polymers?

Natural gas requirements vary by polymer:

– Ethylene Production:

– 1 ton of ethylene needs ~1.2–1.5 tons of ethane.

– 1 ton of ethane requires ~3,000–4,000 cubic feet of natural gas.

– Polymer Yield:

– 1 ton of ethylene yields ~0.95 tons of PE.

– Propylene-to-PP yield is ~0.97 tons.

– PVC uses ~0.6 tons of ethylene per ton, with chlorine reducing gas dependency.

Example Calculation:

– For 1 million tons of PE:

– Ethylene: ~1.05 million tons.

– Ethane: ~1.26–1.58 million tons.

– Natural gas: ~3.78–6.32 billion cubic feet (bcf).

| Table 3: Natural Gas Requirements (Approximate) | |||

| Polymer | Ethylene/Propylene (tons) | Ethane (tons) | Natural Gas (bcf) |

| 1M tons PE | 1.05M | 1.26-1.58M | 3.78-6.32 |

| 1M tons PP | 1.03M (propylene) | 1.24-1.55M | 3.72-6.20 |

| 1M tons PVC | 0.6M (ethylene) | 0.72-0.9M | 2.16-3.6 |

Source: EIA. (2024). Natural Gas Liquids Primer.

7. What Is the Global Supply and Demand Situation?

Supply:

– Global capacity for PE, PP, and PVC is ~310 million tons (2024), with natural gas-derived polymers dominant.

– Key regions: North America (shale gas), Middle East (low-cost ethane), Asia (China’s expansions).

– New crackers in the USA and China add ~5% capacity annually.

Demand:

– Demand is ~290 million tons (2024), with a 3.5% CAGR projected to 2030.

– Drivers: Packaging (45% of PE), construction (55% of PVC), automotive (25% of PP).

– Asia-Pacific consumes ~50%, North America ~18%, Europe ~14%.

Note: Oversupply in China and tariff uncertainties may suppress margins, challenging industry claims of robust growth.

Source: ICIS. (2023). Polyethylene Prices, Analytics and Forecasts. (https://www.icis.com/explore/commodities/chemicals/pe/)

8. What Are the Current Prices and Likely Future Trends?

Current Prices (2025):

– HDPE: $950–$1,150/ton.

– PP: $1,050–$1,250/ton.

– PVC: $850–$1,050/ton.

– Prices are lower in Asia due to oversupply, higher in Europe due to energy costs.

Future Trends:

– 2025–2027: Prices may soften due to capacity additions in China and the USA.

– 2028–2035: Demand growth in India and Africa could raise prices by 2–3% annually, though recycling and bio-plastics may cap gains.

– Factors: Tariffs, energy prices, and green policies will shape trends.

Source: Polymerupdate. (2025). Daily Polymer Pricing. (https://www.polymerupdate.com/)

9. Is It Profitable to Use Natural Gas for Producing Polymers Instead of as a Fuel?

Analysis:

– Fuel Use: Natural gas at $3–$4/MMBtu (USA, 2025) yields low margins in energy markets.

– Polymer Production: Ethane ($0.15–$0.25/gallon) to PE ($950/ton) offers ~45–55% gross margins after costs.

– Regional Edge: The USA and Middle East benefit from cheap NGLs, unlike Europe or Asia.

– Caveat: Capital-intensive plants and potential oversupply risks temper profitability.

Conclusion: Polymer production is more profitable than fuel use in low-cost regions, but long-term viability hinges on demand stability and environmental regulations.

Source: Dallas Fed. (2024). Energy Indicators. (https://www.dallasfed.org/research/energy/indicators/2024/en2402)

10. What Are the Ecological Aspects of Production and Consumption?

Impacts:

– Production:

– Emissions: ~1.8 tons CO₂/ton of polymer; methane leaks add to GHG footprint.

– Energy: ~12 MWh/ton of polymer.

– Water: High usage for cooling, straining arid regions.

– Consumption/Disposal:

– Waste: ~10% of plastics recycled globally; most landfilled or incinerated.

– Microplastics: PE, PP, and PVC contribute to pervasive pollution.

Mitigation:

– Carbon Capture: Limited adoption due to cost.

– Recycling: Chemical recycling trials underway, but scale is small.

– Bio-Feedstocks: Bio-ethylene from sugarcane tested, yet fossil-based remains dominant.

| Table 4: Ecological Footprint | ||

| Aspect | Impact | Mitigation Strategy |

| CO2 Emissions | 1.8 tons/ton | CCS, Renewables |

| Plastic Waste | ~90% non-recycled | Chemical Recycling |

| Ware Use | High | Recycling Systems |

| Microplastics | Widespread pollution | Waste Management |

Note: Industry claims of ‘sustainable plastics’ often overstate progress, as recycling rates and CCS adoption lag.

Source: ScienceDirect. (2024). Carbon Footprint of PVC, PE, and PP Piping. (https://www.sciencedirect.com/science/article/pii/S2352484720315985)

Conclusion

The market of polymers derived from natural gas is around USD 400 billion. It makes better business sense to convert the natural gas into polymers rather than burning it as a fuel. However, the research and development side of the industry would need to fast-track the technologies and methods to cater to the ecological concerns. /// nCa, 17 April 2025 [to be continued . . .]

Additional Sources:

– Grand View Research. (2023). Polypropylene Market Size, Share & Growth Report, 2030. (https://www.grandviewresearch.com/industry-analysis/polypropylene-market)

– Straits Research. (2025). Global Polyvinyl Chloride Market Overview, 2031. (https://straitsresearch.com/report/polyvinyl-chloride-market)

Chemical Market Analytics. Value-Chain

(https://chemicalmarketanalytics.com/value-chain/plastics-polymers/)

ICIS

(https://www.icis.com/explore/commodities/chemicals/pe/)

Dallasfed

(https://www.dallasfed.org/research/energy/indicators/2024/en2402)